What measures are you using to determine your company’s performance? How do you know if you have had a good day, week, month, or even year? You look to your performance measures, of course. But as you step back and give thoughtful evaluation, do you see a set of performance measures that provide timely, effective, and relevant insight, or do you see a collection of measures that tell you about outcomes but little about the performance of upstream operations?

Just like you can tune up your operations to be more effective and competitive, you can also tune up your performance measures to reflect contemporary conditions and opportunities.

Metrics Drive Behavior

The performance metrics you use might not have changed in a while. Perhaps they’ve been static for years. But has your company remained static? Probably not. Customers and customer demands change; equipment is updated to reflect technological improvements; and the flow within the operations changes, especially if you’re aggressively pursuing your lean journey. If metrics do not keep pace, you may unintentionally be inhibiting your company’s performance.

Effective metrics and performance measures will drive behavior. You should revisit them to make sure they are still driving the right behavior—hence the need for a periodic tuneup.

Focus on Behavior

Keeping your performance measures relevant is serious business. It would be easy to make knee-jerk decisions based on the latest issue, complaint, or problem. But metrics developed in this way probably don’t tell you what you need to know and have a short shelf life. You’re likely to replace it with another measure that feels good in the moment.

Selecting and tuning performance measures is a process, and treating it as such should help you gather meaningful, lasting information for guiding the business. Equally important, you develop mechanisms that influence outcomes and drive the desired behavior.

What behaviors do you want to affect? Do they focus on cost, quality, or delivery? Maybe you need to influence speed, cleanliness, or safety. If you are tuning an existing metric, have employees drifted away from its original intent, or are they simply failing to comply? Answering these sorts of questions will help you build clarity around the desired behavior and intent.

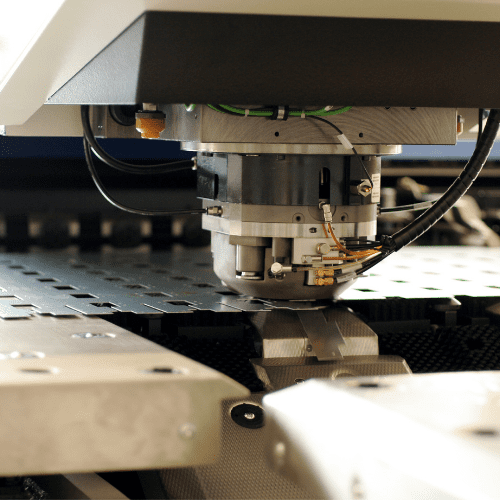

Read more: Tuning up a metal fabricator’s performance measures