Presses of all types—mechanical, pneumatic, servo, and hydraulic–have their place and offer unique advantages. However, over the past 50 years, hydraulic presses have trended toward greater utility. Today’s hydraulic presses are faster and more reliable than ever, and the technology has gone through significant changes and refinements. Improvements in seals, pumps, hoses, and couplings have nearly eliminated leaks and minimized maintenance.

An examination of hydraulic press technology and the press’s anatomy, as well as its benefits, limitations, tips for selection, and automation options, can net the best utility from a press.

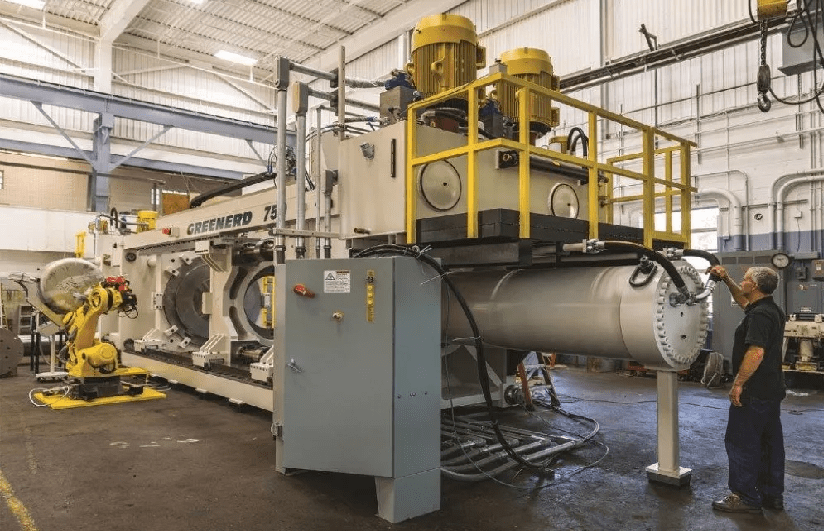

Hydraulic Press Anatomy, Types

Press Structure. These are the major components and features of the hydraulic press structure:

1. Cylinder. The cylinder assembly comprises a cylinder, piston, ram, packing, and seals. Piston diameter and oil pressure determine the force (tonnage) that a press can deliver.

2. Frame. The frame is the main structure of the press containing the cylinders and the working surfaces.

3. Stroke Control. Stroke length can be set for any distance within the stroke limits of the cylinder in the stroke control. Adjustments include the top of stroke, pre-slowdown point, and bottom of stroke.

4. Throat Clearance. The distance from the vertical centerline of the ram to the frame member behind the bed is called the throat clearance. This distance determines the maximum piece size that can be positioned with the part centerline under the center of the ram.

5. Daylight. This is the vertical clearance from the top of the bolster to the underside of the ram in its maximum up position. This term is sometimes confused with the mechanical press term shut height. Shut height is the clearance over the bed with the ram fully down. Daylight describes the maximum vertical die capacity of the press.

Read more: Stamping 101: Anatomy of a hydraulic press