Have you heard of roll forming? Consider this.

According to ISQ Directory:

Chapter One – What is roll forming?

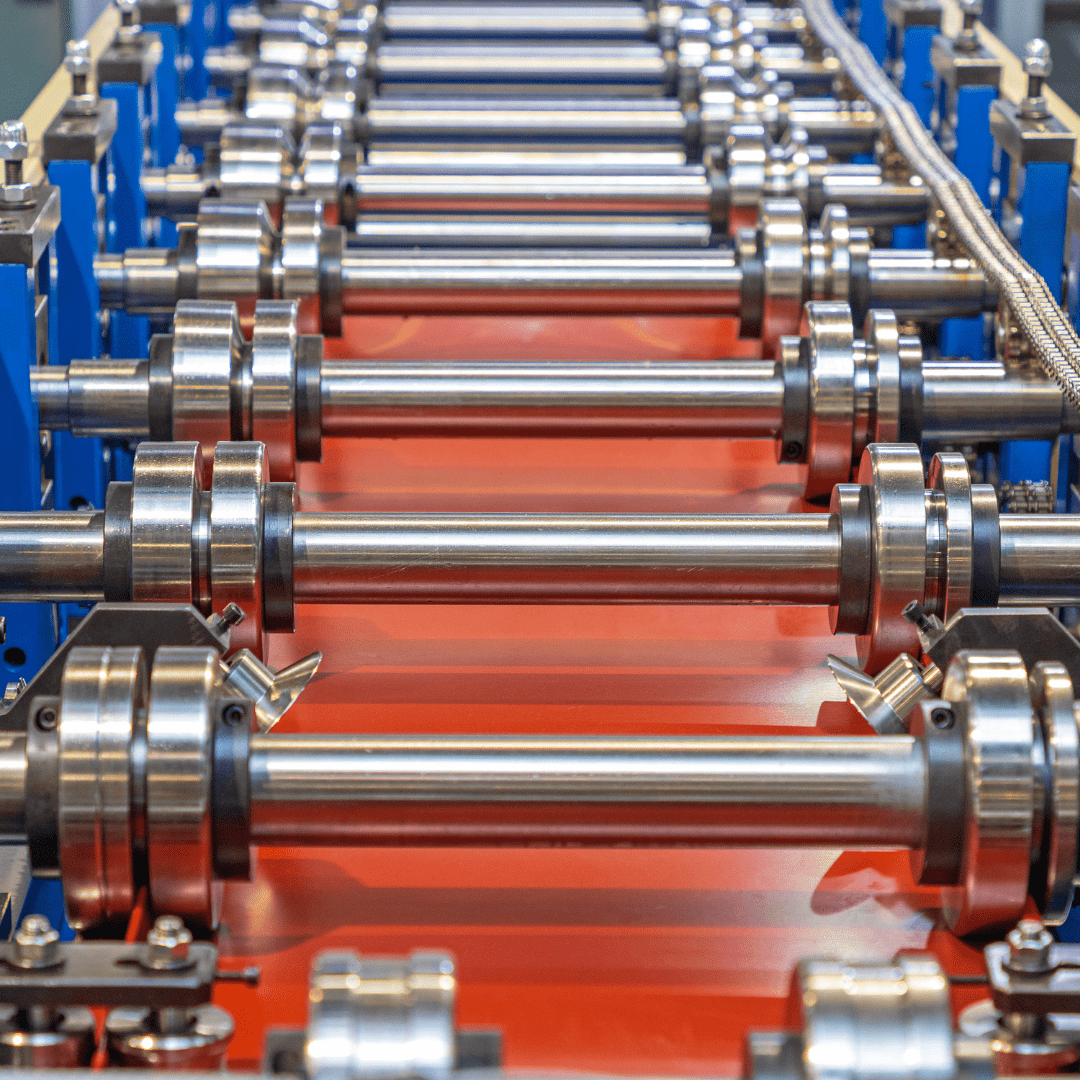

“Roll forming is a process that uses a set of precisely placed rollers to perform incremental bending to a continuously fed strip of metal. The rollers are mounted in sets on a consecutive stand with each roller completing one small step of the process.

“Rollers are carefully crafted using a flower pattern, which identifies the sequential changes to the metal strip. The shape of each roller is created from the individual sections of the flower pattern.

“Each of the colors in the above flower pattern illustrates one of the incremental bends used to complete the part. The individual colors are a single bending operation. CAD or CAM renderings are used to simulate the roll forming process so that errors or flaws can be prevented prior to production. Using software applications, engineers can select calibrations and profiles for folding or bending angles to create new geometries by clicking their mouse.

Chapter Two – Roll Forming Process

“Each roll forming manufacturer has a different set of steps for their roll forming process. Regardless of the variations, there are a set of basic steps all producers use.

“The process begins with a large coil of sheet metal that can be from 1 inch to 30 inches wide with a thickness of 0.012 inch to 0.2 inch. Before a coil can be loaded, it has to be prepared for the process.

“The above diagram represents each step of roll forming from the feeding of the coil to the cutoff and discharge at the end of the process. Below is a description of each step.

Steps of the Roll Forming Process:

“Uncoiling: Metal coils may become set during storage and have a tendency to stay coiled and become distorted. To correct the problem, the coil is loaded onto the uncoiler, seen below, and fed through a flattener to remove the coil set. The lead end is trimmed to allow for smooth feeding into the pre-press process.

“Part of the pre-press operation may be a tapering of the beginning of the feed coil to make it easier for it to slide into the forming rollers.

“Pre-press treatment: Before the metal from the coil is fed into the roll forming rollers, it may need applications added as can be seen in the image below, which can involve adding slots, holes, or slits.

“Roll forming: At this stage, the material is progressively shaped. A typical roll forming machine can consist of 10 to 24 pairs of roller die stands. The machine is individually or gang driven to force the ribbon of metal through the rollers that gradually shape it to the dimensions of the flower pattern.

“Cutoff and discharge: Parts are cut to length as they are in motion, which increases the efficiency and speed of the roll forming process. Once they are cut, they are discharged to a run-out table to be placed for shipment or further processing.

“Secondary processes: There are a variety of ways secondary processes can be performed. Some can be completed as the part comes off the cutoff, while others may have to be performed at another station.

“The image below has samples of some of the listed secondary processes, which include:

- “Punching

- “Notching

- “Tight tolerance forming

- “Straightening

- “Adding other components

- “Minor assembly

Lubricant

“With any metal forming process, friction plays an important role, which is the resistance produced when two bodies make contact. It is a means of energy dissipating that causes a rise in temperature where two surfaces meet. The temperature is further enhanced by the speed of the process.

“Lubrication is used in the roll forming process to reduce friction between the rolls and metal to prevent tool wear. Friction is a necessary part of the rolling process and an important part of shifting the metal forward between the rollers. It should not be eliminated or reduced below an appropriate level. The need for friction has to be considered when choosing a lubricant.

“Roll forming uses fluid lubricants with a low viscosity that include paraffin for non-ferrous metals such as aluminum and copper. Lubricants increase the rate of production, which is determined by the thickness of the material, number of roll stations, and the amount of bending. Below is an example of a roll forming process that uses a chlorine free lubricant.

Chapter Three – Technical Advances in Roll Forming

“Technological advances have had a significant impact on the roll forming industry. The methods and processes from computerization has improved dimensional accuracy and adherence to tolerances. Below is a description of a few of the significant improvements.

Computer Numerically Control (CNC)

“A CNC machine can be programmed to control metal processing and give instructions to automatic tools, equipment, and rollers. They decide the sequence of machine operations, perform trial runs, and can be programmed with specific part geometries to follow the flower pattern.

“Depending on the type and design of a profile, CNC roll forming machines can be adjusted without the need to change tools. Overall measurements can be continuously varied including non-symmetrical ones as well as sheet thickness changes. The image below is the display screen from a CNC roll forming machine with its set of commands.

Computer Aided Design (CAD) or Manufacturing (CAN)

“Designing for roll forming involves three engineering design elements: geometry, length, and type of material. The designs created in CAD/CAM can be easily transferred to CNC programming.

“Geometry – Roll forming can use CAD to reduce complex, multiple component parts into a single structure. Several simple components can be combined to form a single complex shape.

“Length – Roll forming is ideal for long parts with high production runs. Stamped and press braked parts can be converted to roll forming using CAD programming.

“Metal – CAD can test a metal for its appropriateness for the application without having to make a production run or prototype…

Programmable Logic Controller

“A PLC is very similar to a CNC machine. Like a CNC machine, PLCs are specialized computer control systems designed to control machines and their processes. They continuously monitor a device and make adjustments. In roll forming, the operator enters the commands for cutting lengths and quantities. The more complicated the required operation; the more commands have to be entered, such as hole punching, slot cuttings, and other pre-press functions. The white device in the image below is the PLC controller for a rail guide roll forming machine.

TIG Welding and Lasers

“TIG, tungsten inert gas welding, uses a tungsten electrode to create the weld in a roll formed shape. As the rolled form exits the rollers, and before it is cut, it is automatically welded by either a laser or TIG welder. For the operation to be successful, the radii of the rolled form have to meet perfectly. Below are images of weld rolled forms for tubing.

Chapter Four – Benefits and Advantages

“Roll forming is a cost effective process for shaping metal coils into custom designed profiles. It is used by several industries to produce components for automobiles and appliances to aircraft and construction industries. Listed below are some of the benefits and advantages roll forming offers.

Efficiency

“The speed of roll forming is due to the long coils of metal it uses that are rapidly fed into the forming machine. Since the machine is self-feeding, there is little need for human monitoring, which lowers the cost of labor. Punching and notching during pre-feeding avoids the need for secondary operations.

Cost savings

“Metals do not need to be heated for roll forming, which significantly lowers energy costs. The careful control and lubrication of moving parts reduces tool wear and the cost of component replacement. The smooth finishes of completed parts removes the need for secondary processes such as deburring or trimming of flash. Parts are produced in large quantities reducing the cost of the final product.

Flexibility

“Complex and intricate cross sections can easily be produced using ferrous and non-ferrous metals. In some processes, it is not possible to shape a metal that has been painted, plated, or coated. Roll forming can easily shape them regardless of the type of finish.

Quality

“Products are more uniform and consistent across a complete run. Tolerances are very tight with extremely precise dimensions. Sharp, clean contours are maintained with the absence of die marks or deformities.

Length of parts

“Since the metal is fed into the machine, any length can be produced using the same tooling for any part.

Less scrap

“Roll forming produces one to three percent scrap for each production run, which is far less than any other metal working process. The lower amount of scrap lowers the cost of working with expensive metals.

Repeatability

“A major problem with bending metal is residual stress, which negatively affects repeatability. The rapid processing of roll forming helps metals retain their residual stress as well as any loss of weld seam control.

Chapter Five – Metals Used in Roll Forming

“Roll forming can shape any ferrous or non-ferrous metals and their alloys. The types of metals used by manufacturers determines the adjustments that must be made to each bending stage of the roll forming process. The key factors are thickness and ductility as well as the flow stress, which determines the amount of force necessary to shape the metal. The yield point, the point at which a metal bends, is higher at a lower temperature necessitating an increase in the amount of force, which has to be factored into the roll forming machine.

“Listed below are seven metals that are commonly used in roll forming separated into ferrous and non-ferrous metals.

Ferrous metals – Contains iron

Steel:

- “Made of iron

- “Malleable below its melting point without requiring special heat treatment.

- “Free from slag

- “Contains small amounts of silicon and manganese

- “Has trace quantities of sulfur and phosphorus

Stainless Steel:

- “Has a high percentage of chromium

- “Strain and corrosion resistant

- “Resistant to weak mineral acids, oxidation, organic acids, and caustic materials

Galvanized Steel:

- “Coated with zinc

- “Is a heat treated metal

- “Has a bonded coating of zinc-iron alloy

Non-Ferrous metals – Does not contain iron

Aluminum:

- “Malleable

- “Lightweight

- “Resistant to corrosion

- “Has a layer of aluminum oxide

Brass:

- “Copper and zinc alloy

- “Corrosion resistant

- “Bronze is another type

- “Malleable

Copper:

- “Has electrical conductivity.

- “Primary component in non-ferrous alloys

Lead:

- “Has high density

- “Low melting point

- “Tarnishes slowly

- “Ductile

- “Poor electrical conductor

- “Resistant to corrosion

Chapter Six – Types of Roll Forming Processes

“Every roll forming manufacturer uses a unique set of rolling processes to create their products. Some specialize in tubing, while others produce roofing and siding. The most common types of rolling are:

- “Shape Rolling

- “Ring Rolling

- “Roll Bending

- “Flat Rolling

- “Plate Rolling

“Below is a discussion of these methods:

Roll Forming Methods

A) Roll Bending

“Roll bending can be used for thick large metal plates. Three rollers bend the plate to produce the desired curve. The placement of the rollers determines the exact bend and angle, which is controlled by the distance between the rollers.

B) Flat Rolling

“The basic form of roll forming is when the end material has a rectangular cross-section. In flat rolling, two working rollers rotate in opposite directions. The gap between the two rollers is slightly less than the thickness of the material, which is pushed through by the friction between the material and the rollers, which elongates the material due to the decrease in material thickness. The friction limits the amount of deformation in a single pass making several passes necessary.

C) Shape Rolling/Structural Shape Rolling/Profile Rolling

“Shape rolling cuts different shapes in the workpiece and does not involve any change in the thickness of the metal. It produces molded sections such as irregular shaped channels and trim. Shapes formed include I-beams, L-beams, U channels, and rails for railroad tracks.

D) Ring Rolling

“In ring rolling, a ring of small diameter workpiece is rolled between two rollers to form a ring of larger diameter. One roller is the drive roller, while the other roller is idle. An edging roller ensures that the metal will have a constant width. The reduction in width of the ring is compensated for by the diameter of the ring. The process is used to create seamless large rings.

E) Plate Rolling

“Plate rolling machines roll sheets of metal into tightly shaped cylinders. The two different varieties of this type of equipment are four roller and three roller. With the four roller version, there is a top roller, pinch roller, and side rollers. The three roller version has all three rollers producing pressure with two on the top and one on the bottom. The diagram below is a four roller systems forming a cylinder.

Chapter Seven – Roll Forming Machines

“There are several varieties of machines used to roll metals. The type depends on the number of spindles that are used. The spindles of the machine are mounted on a base plate that is a base table for the rolling process. Once the rollers are mounted, they are aligned with the spindles, the rotation of which shapes the metal. Spacers hold the rolls in position and allow the spindles to easily act on the metal sheets.

“Every manufacturer has their own version of a roll forming machine. Listed below are descriptions of a few common versions.

Stud and track

“Stud and track machines produce assembly frames for strong, lightweight partitions, which can be up to 32 feet with varying thicknesses. These machines can form studs or track from 3 5/8” to 8” with 26 to 14 gauge steel and 1 5/8” and 2 1/2” members

Angle

“Angle roll forming machines use high tensile strength steel for form equilateral or unequal perpendicular angles, the most basic of the rolled formed profiles. Framing is the primary use of roll formed angles, but they can also be used for rails, posts, supports, and brackets.

Beam

“Beam roll forming is used to produce box beams for construction. The designs produce fluted beam profiles for floor decking and framing. Beams are made from high tensile strength steel with double thickness flanges and single thickness webbing for additional strength.

Seamless

“The primary use for seamless roll forming is the manufacturing of tubing, which can be square, round, oval, or rectangular. The TIG process is used at the end of the roll forming process to weld the rolled tubing together as can be seen in the diagram. As with many parts from roll forming, tubing is made from a wide variety of ferrous and non-ferrous metals.

Wrap

“Wrap roll forming machines form a wrapped L-shaped edge or flange on sheet metal. Wrap machines are very similar to a long dinner table with a set of rollers running the length of the table. They can reach speeds of fifty feet per minute to create either complex or simple flanges.

Chapter Eight – Applications and Products

“Roll forming has become the first choice for the manufacture of metal related products due to the high quality, exacting tolerances, rapid production, dimensional accuracy, and lower cost. All metal based industries use roll forming from building construction to aircraft manufacturing. Below is a short list of the applications and products produced by roll forming.

“Door and window hardware

“Metal fencing

“Computer casings and components

“Metal furniture components

“Rain gutters and house siding

“The items listed above are only a few of the wide variety of items we use every day that are rolled formed. Others include desk drawer slides, steel support framing, metal tubing, construction flashing, roofing materials, house and building siding, and exteriors of aircraft and automobiles to name a few.

Conclusion

- “Roll forming is one of the fastest methods of producing products of any length with accurate tolerances and dimensions.

- “Roll forming is a method of bending and shaping a metal strip into a predetermined form by passing the strip through a series of spaced rollers.

- “Computerized roll forming is able to create and test parts and products before they are sent to production.

- “The methods of roll forming include bending, wrapping, ring rolling, and shaping to name a few.

- “Any type of ferrous or non-ferrous metal can be used in roll forming as long as it has the proper ductility.

- “The advantages of roll forming include cost savings, flexibility, speed, reduced scrap, and energy savings.”