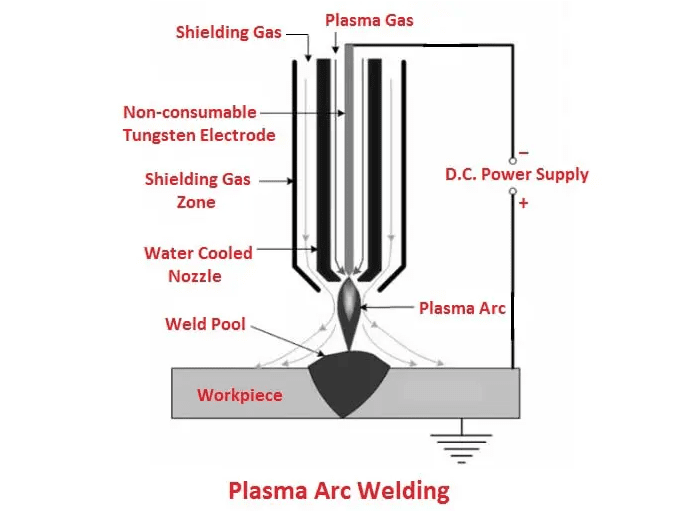

Plasma arc welding is an arc welding process using heat produced by a compressed arc between a tungsten non-consumable electrode and another workpiece (transferred arc process) or water-cooled constricting nozzle (non-transferred arc process).

The plasma is a gaseous mixture of positive ions, electrons, and neutral gas molecules. The transferred arc process produces plasma jets of high energy density and can be utilized for high-speed welding and cutting ceramics, copper alloys, steels, aluminum, nickel alloys, and titanium alloys.

The non-transferred arc process produces a plasma of relatively low energy density. It is used for welding and plasma spraying (coating) of various metals. Since the workpiece in non-transferred plasma arc welding is not a part of the electric circuit, the plasma arc torch may move from one workpiece to others without extinguishing the arc.

Working Principle of Plasma Arc Welding

The PAW works on the principle when a sufficient amount of energy is provided to any inert gas, some of its electrons are released from their nucleus but travel with it.

After the electrons move, the atoms are converted into a hot ionized state. This is the most common condition of the substance which is known as the fourth state of matter.

These ionized atoms have high temperatures that are used to join the two plates. This is the basic principle of PAW. This welding is a form of TIG welding in which a non-consumable tungsten electrode is used to generate the arc.

Read more: PLASMA ARC WELDING: DEFINITION, WORKING, EQUIPMENT, APPLICATIONS, ADVANTAGES