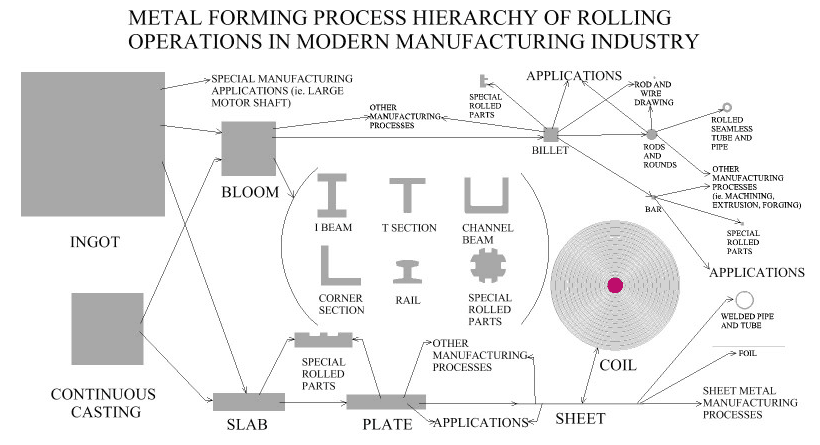

Metal rolling is one of the most important manufacturing processes in the modern world. The large majority of all metal products produced today are subject to metal rolling at one point in their manufacture. Metal rolling is often the first step in creating raw metal forms. The ingot or continuous casting is hot rolled into a bloom or a slab, these are the basic structures for the creation of a wide range of manufactured forms. Blooms typically have a square cross section of greater than 6×6 inches. Slabs are rectangular and are usually greater than 10 inches in width and more than 1.5 inches in thickness. Rolling is most often, (particularly in the case of the conversion of an ingot or continuous casting), performed hot.

At a rolling mill, blooms and slabs are further rolled down to intermediate parts such as plate, sheet, strip, coil, billets, bars and rods. Many of these products will be the starting material for subsequent manufacturing operations such as forging, sheet metal working, wire drawing, extrusion, and machining. Blooms are often rolled directly into I beams, H beams, channel beams, and T sections for structural applications. Rolled bar, of various shapes and special cross sections, is used in the machine building industry, as well as for construction. Rails, for the production of railroad track, are rolled directly from blooms. Plates and sheets are rolled from slabs, and are extremely important in the production of a wide range of manufactured items. Plates are generally considered to be over 1/4″, (6mm), in thickness. Plates are used in heavy applications like boilers, bridges, nuclear vessels, large machines, tanks, and ships. Sheet is used for the production of car bodies, buses, train cars, airplane fuselages, refrigerators, washers, dryers, other household appliances, office equipment, containers, and beverage cans, to name a few. It is important to understand the significance of metal rolling in industry today, as well as its integration with other manufacturing processes.

Principles Of Metal Rolling

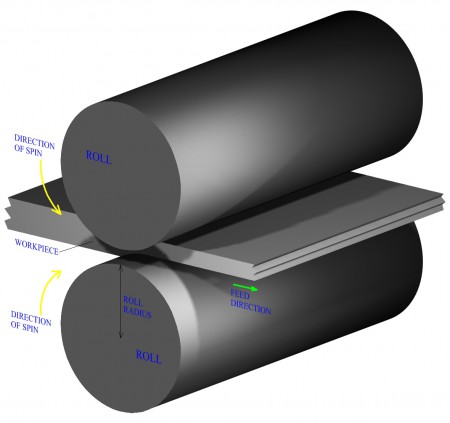

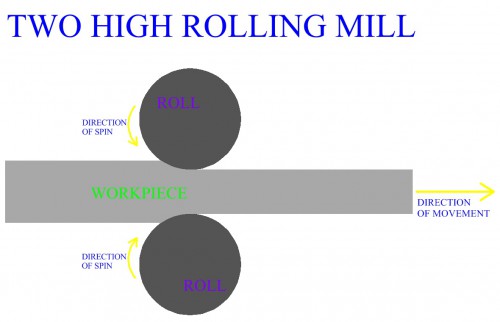

Most metal rolling operations are similar in that the work material is plastically deformed by compressive forces between two constantly spinning rolls. These forces act to reduce the thickness of the metal and affect its grain structure. The reduction in thickness can be measured by the difference in thickness before and after the reduction, this value is called the draft. In addition to reducing the thickness of the work, the rolls also act to feed the material as they spin in opposite directions to each other. Friction is therefore a necessary part of the rolling operation, but too much friction can be detrimental for a variety of reasons. It is essential that in a metal rolling process the level of friction between the rolls and work material is controlled, lubricants can help with this. A basic flat rolling operation is shown in figure:130, this manufacturing process is being used to reduce the thickness of a workpiece.

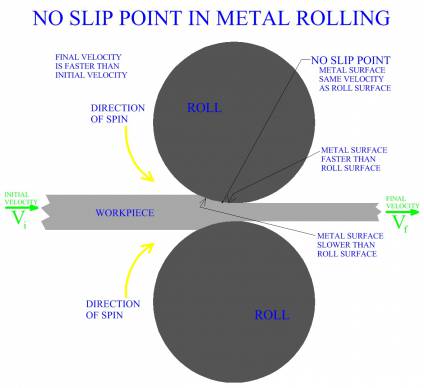

During a metal rolling operation, the geometric shape of the work is changed but its volume remains essentially the same. The roll zone is the area over which the rolls act on the material, it is here that plastic deformation of the work occurs. An important factor in metal rolling is that due to the conservation of the volume of the material with the reduction in thickness, the metal exiting the roll zone will be moving faster than the metal entering the roll zone. The rolls themselves rotate at a constant speed, hence at some point in the roll zone the surface velocity of the rolls and that of the material are exactly the same. This is termed the no slip point. Before this point the rolls are moving faster than the material, after this point the material is moving faster than the rolls.

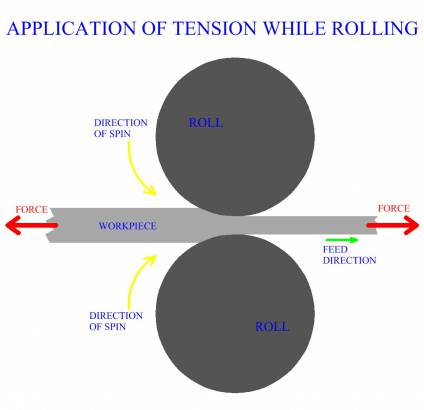

Sometimes in metal rolling practice, tension, (force), is applied to a work piece as it is being rolled. This tension may be applied to the front, (front tension), the back, (back tension), or both sides. This technique will assist the forces necessary to form the work, and is usually used on hard to roll materials.

Spreading In Metal Rolling

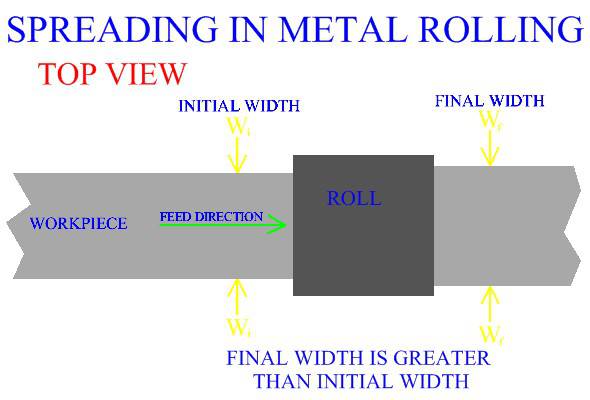

In metal rolling operations, the plastic deformation causing a reduction in thickness will also cause an increase in the width of the part, this is called spreading.

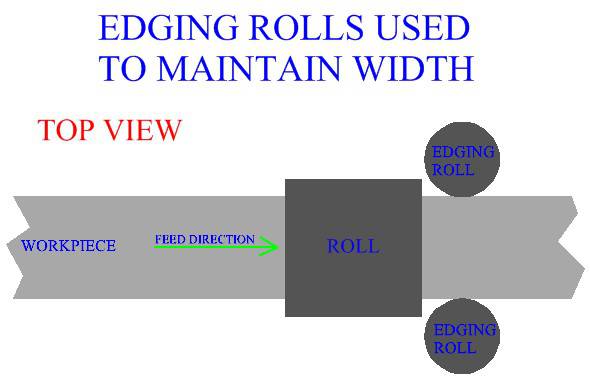

When the work being processed has a high width to thickness ratio, the increase in width is relatively small and usually of no concern in industrial manufacturing practice. In cases of low width to thickness ratios, such as a bar with a square cross section, spreading can be an issue. Vertical rolls can be employed to edge the work and maintain a constant width.

Grain Structure In Metal Rolling

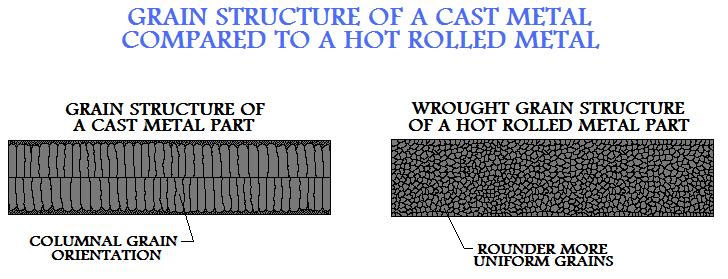

In common industrial manufacturing industry, the ingot or continuous casting is hot rolled into a bloom or slab. In addition to producing a useful shape for further processing, the hot rolling process converts the cast grain structure into a wrought grain structure. The initial cast material will possess a non uniform grain structure, typically large columnar grains that grow in the direction of solidification. These structures are usually brittle with weak grain boundaries. Cast structure characteristically contains many defects such as porosity caused by gases, shrinkage cavities, and solid inclusions of foreign material that becomes trapped in the metal, such as metallic oxides.

Rolling a metal above its recrystallization temperature breaks apart the old grain structure and reforms a new one. Grain boundaries are destroyed and new tougher ones are formed, along with a more uniform grain structure. Metal rolling pushes material, closing up vacancies and cavities within the metal. In addition, hot rolling breaks up inclusions and distributes their material throughout the work.

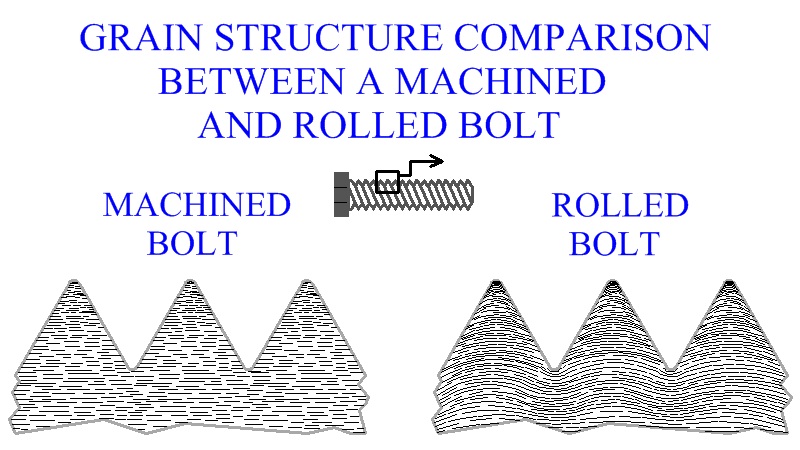

It should be apparent that the advantages of metal forming are not just in the creation of useful geometric forms but also in the creation of desired material properties as well. Cold rolling processes as discussed earlier, are useful for imparting strength and favorable grain orientation. Since metal rolling affects grain orientation, a part can be rolled in a way as to create grains oriented in a direction such that they give directional strength to a part useful to that part’s specific application. An example of this can be the difference in grain structure between the threads of a machined bolt and a rolled bolt. The favorable grain orientation of the cold rolled bolt will give it directional strength beneficial to its application.

Rolls For Metal Rolling

Metal rolling manufacturing can produce a wide range of different products. The width of rolled work can be as much as several meters, or narrower than a thousandth of an inch. Metal rolling manufacture also creates rolled work over a wide range of thicknesses. Metal plates for some boilers may be rolled to a thickness of 12 inches, while foil for wrapping cigarettes and candy can be .0003 inches thick. Rolls used in metal rolling are of various sizes and geometries. In flat rolling processes, during industrial manufacture, the rolls may typically be 24 to 54 inches in diameter. In some metal rolling operations, in the forming of very thin work, the rolls can be as small as 1/4 inch.

Rolls are subject to extreme operating conditions during the metal rolling process. Conditions include, tremendous forces, bending moments, thermal stresses, and wear. Roll materials are selected for strength, rigidity, and wear resistance. Roll materials vary dependent upon the specific metal rolling process. Common roll materials are cast iron, cast steel, and forged steel. Forged rolls are stronger and more rigid than cast rolls but are more difficult to manufacture. In industrial metal manufacturing processes, rolls are commonly made from nickel steel or molybdenum steel alloys. With metal rolling operations of certain materials, rolls made of tungsten carbide can provide extreme resistance to deflection.

Roll Deflections

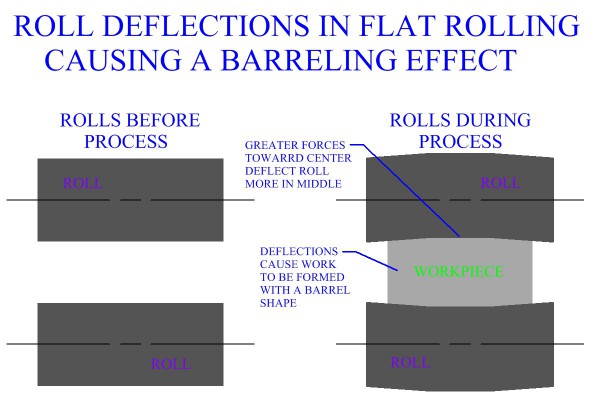

Strength and rigidity are important characteristics of the rolls used to form product in metal rolling manufacture. The particular attributes of the rolls will affect dimensional accuracy as well as other factors in the operation. During the rolling process great forces act upon the rolls. Rolls will be subject to different degrees of deflection. In any particular metal rolling process, it is important to understand how these deflections will affect the rolls and hence the work being rolled. The rolls initially start out flat. During a basic flat rolling operation, it can be observed that the work material will exert greater force on the rolls towards the center of the material than at its edges. This will cause the rolls to deflect more at the center, and hence gives the work a greater thickness in the middle.

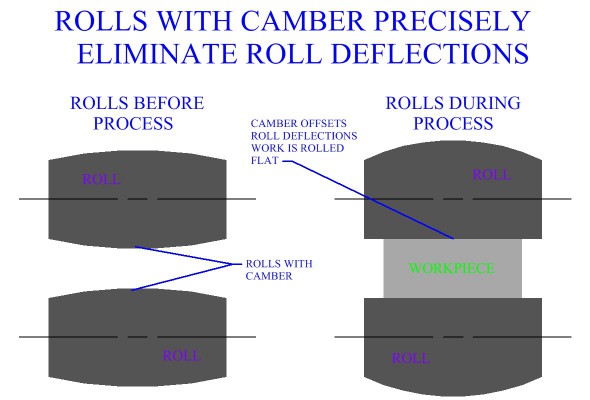

To solve this problem in industrial metal rolling manufacture, the rolls are often ground so that they are thicker towards the center in such a way as to exactly offset the deflection that will occur during the process. This extra thickness is called camber.

The camber that must be ground into a roll is very specific to a particular work width, material, and force load. A roll must usually be manufactured for only one metal rolling process. In some industrial metal rolling processes, rolls are given temporary camber by applying forces through their bearings. Another way that rolls deflect is by the shortening of their radius along the contact of the work. In other words, they flatten like a tire on a car might. This type of deflection is important to consider in manufacturing practice, as it will affect roll radius calculations and friction.

Defects In Metal Rolling

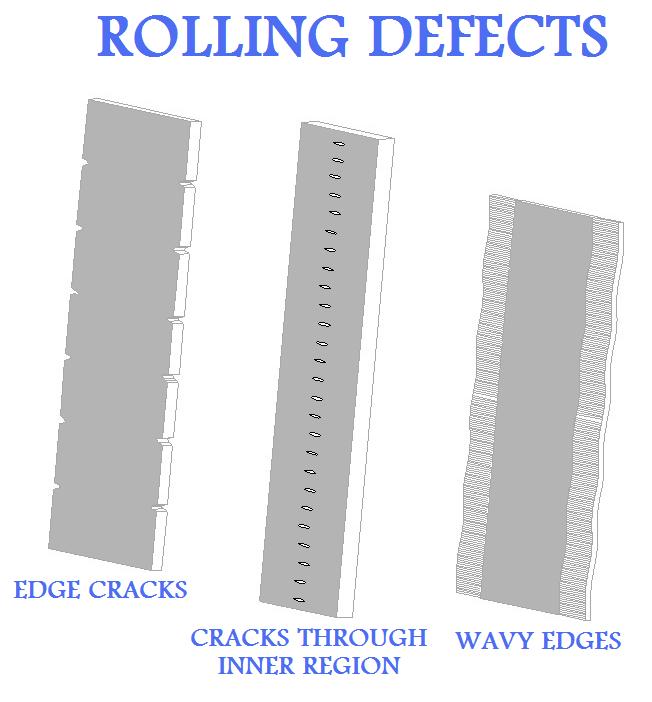

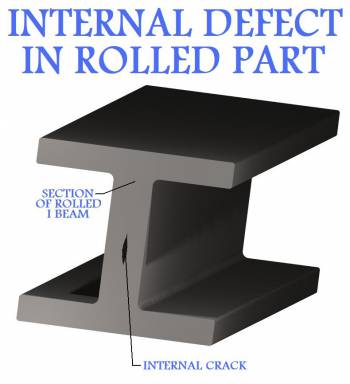

A wide variety of defects are possible in metal rolling manufacture. Surface defects commonly occur due to impurities in the material, scale, rust, or dirt. Adequate surface preparation prior to the metal rolling operation can help avoid these. Most serious internal defects are caused by improper material distribution in the final product. Defects such as edge cracks, center cracks, and wavy edges, are all common with this method of metal manufacturing.

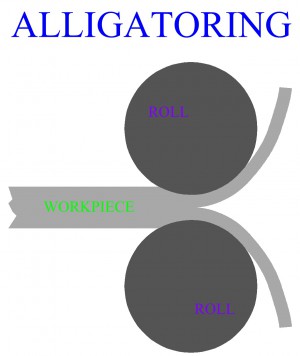

Often times a sheet is not defective, it is just not flat enough. In sheet metal industrial practice, a sheet may be passed through a series of leveling rolls that flex the sheet in opposite directions to flatten it. Another interesting defect that can occur in flat rolling is alligatoring, where the work being rolled actually splits in two during the process. The two parts of the work material travel in opposite directions relative to their respective rolls.

In shape rolling manufacture, a work piece will often experience different amounts of reduction in different areas of its cross section. One of the goals of roll pass design is to properly design a series of reductions in such a way as to mitigate the relative differences in shape change between areas, in order to avoid material defects. Improper reductions of the product can cause warping or cracking of the material. Metal rolling practice is not always the cause of warping or cracking, sometimes defects in the metal being rolled may be the reason.

Rolling Mills

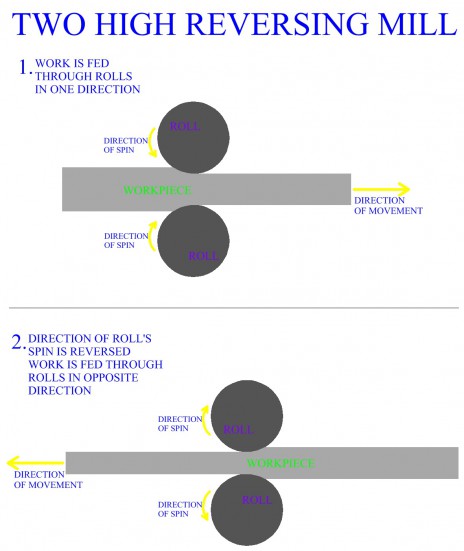

In metal forming industry, rolls themselves do not function in isolation. In a metal rolling process, rolls, stands, bearings, housing, motors, and other mechanical equipment are all a necessary part of the manufacturing operation. The place where all the equipment for metal rolling manufacture is set up is called a rolling mill. Rolling mills often vary in the type, number, and position of rolls. Rolling mill arrangements commonly used in manufacturing industry today include the two high mill, the two high reversing mill, the three high mill, the four high mill, the cluster mill, and the tandem rolling mill.

In the two high reversing mill the direction of spin of the rolls can be reversed. This enables the work to travel through in one direction, then back through in the other direction. A series of reductions can be made using the same set of rolls, by passing the work back and forth. Disadvantages of the two high reversing mill include the mechanical requirements and power to constantly overcome and reverse the angular momentum of the rolls.

The three high rolling mill utilizes the principle of passing the work back and forth to achieve a series of reductions. Unlike the two high reversing mill, the three high mill has three rolls that always spin in the same direction. An elevator mechanism lifts and lowers the work so that it can be passed back and forth through the rolls.

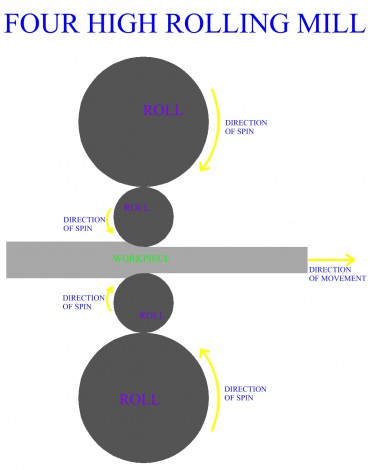

It is known, in metal rolling practice, that the amount of roll force is reduced with a smaller radius of the rolls. Smaller radius rolls, however, deflect easier and must be supported by other rolls. The four high mill uses this principle with two smaller work rolls each supported by a larger backing roll.

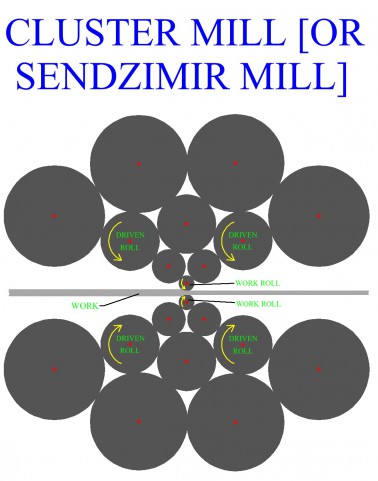

The cluster mill, or Sendzimir mill, uses a small work roll backed up by many other rolls. This extremely rigid setup is often used for cold rolling high strength material to a very thin width.

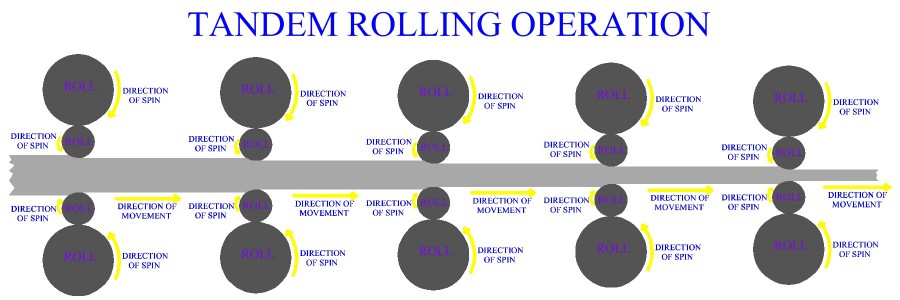

The tandem rolling mill consists of several stands, that the work material constantly passes through. At each stand the thickness of the work strip is reduced a certain amount. The total reduction between the first and last stand can be significant. There are technical problems associated with tandem rolling, caused particularly by the fact that the speed of the work material increases as it passes through each stand. In manufacturing practice, various control systems are used to keep the entire operation synchronized. Once the particular technical problems and initial setup investment is overcome, tandem rolling can provide a great advantage in the cost and productivity of an industrial metal rolling process. Tandem rolling can be even more advantageous when integrated with continuous casting.