When it comes to metal fabrication, adapting to new tech means you are more likely to succeed.

According to Tim Heston with The Fabricator:

“’We’re seeing rapid change in all businesses, but especially in manufacturing, the likes of which we haven’t seen in decades. We’ll see the emergence of a digital divide in manufacturing over the next 10 years. There will be those who invest now and move ahead, and there will be those who don’t and will be left behind.’

“So said John R. Brandt. CEO of Cleveland-based The MPI Group, Brandt spoke to the 300-plus metal processing and fabrication professionals who attended the Fabricators & Manufacturers Association Annual Meeting, held in early March in San Antonio. The overall mood of those who attended remained positive, despite a tumultuous stock market and high uncertainty spurred by COVID-19. Of course, conditions evolved quickly in early March, and some fabricators had changed their outlooks significantly during the ensuing weeks. Even so, despite some unprecedented challenges in the short term, the long term outlook remained bright.

“There’s another root to the positivity that has to do with the ideas behind Brandt’s comments about an environment of rapid change driven by so-called ‘disruptive technology.’ The phrase brings up a list of buzzwords like the industrial internet of things, artificial intelligence, and Industry 4.0. What you call a specific technology and whether it’s ‘disruptive’ might be debatable, but debating it misses the point.

“It boils down to knowing more about a company’s processes, then connecting the dots to perfect and drive those processes in new directions. Doing this might make metal fabrication—the technology, the fab shops, and the supply chains they work within—look very different during the coming years.

“The strategy and technology sessions at the 2020 FMA Annual Meeting—a gathering that also celebrated FMA’s 50th year—drove these points home. Despite stock market gyrations and a mysterious virus, those who adapt and invest will move ahead toward a bright future.

About Knowledge

“During one roundtable discussion, Paul Blizel, vice president, automation division at Ncell, conversed with an operations manager in the audience. They brought up a relatable problem, evident by the quiet chuckles and head nodding.

“The scene is on Monday morning, when material handlers spend several hours sifting through cut parts stored in a tower. Priorities changed, and downstream processes need several pieces sooner than expected. They’re of different thicknesses and, of course, in different cartridges on the tower, buried and hard to find. The part-sorting bottleneck rears its ugly head.

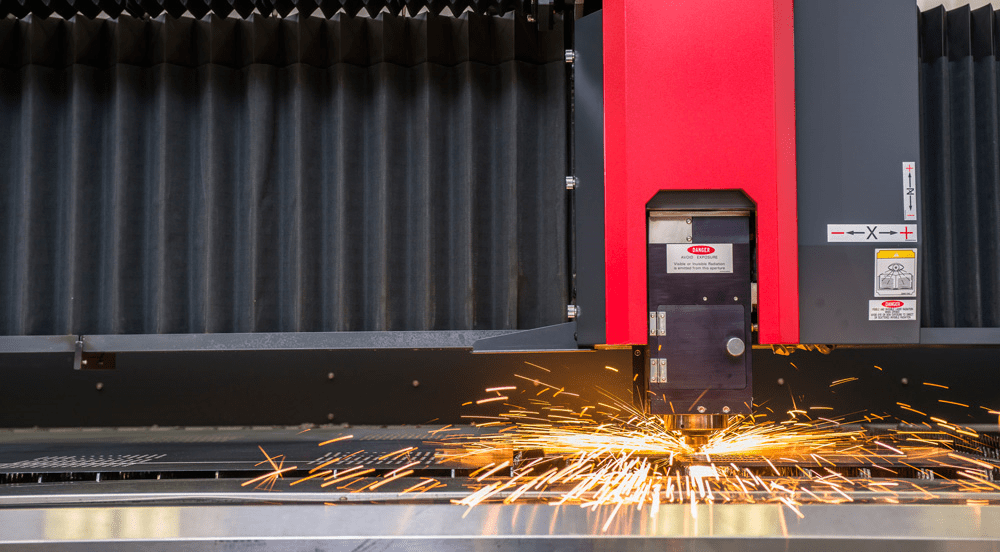

“Blizel called laser cutting a kind of ‘black hole [in parts management], unmanaged and invisible.’

“He added that in these situations, context makes all the difference, especially in these days of dynamic nesting in which parts tied to dozens of different jobs can be arranged onto a single sheet. Without that context, work-in-process (WIP) rises along with overall manufacturing times, and on-time delivery suffers, even as equipment reaches previously unheard-of levels of productivity.

“Context—that is, having the right information at the right time—changes the game. Consider the previous example. If the automated lasers were programmed with schedule priorities in mind, the pieces needed first thing Monday morning would have been cut last and stored at the top of a known cartridge in the tower. In fact, the entire cutting sequence would have balanced material yield (squeezing all the parts you can on a sheet) with the speed of part sorting and flow to downstream operations.

“During the meeting’s technology sessions, maintaining flow was a common theme. Sessions presented by Amada, Bystronic, Mazak Optonics, MC Machinery Systems Inc., and TRUMPF covered how various aspects of technology help keep jobs on the move. It’s a complex problem, considering all the moving puzzle pieces.

“One is varying material thickness, quality, and surface conditions. Certain lasers today have beam control monitors to keep the waist of the beam focus where it needs to be for effective cutting. Travel and other parameters change to adapt to rust and other imperfections.

“New approaches to nesting and cut sequencing consider skeleton integrity and the risk of part tip-ups. Certain cutting modes even make what seem at first glance to be wasteful cuts into scrap. But time spent cutting that scrap into small pieces, allowing them to fall easily through the slats, is a small price to pay to prevent the crash of a cutting head.

“Perhaps most significant is the push toward automated part sorting. Beam conditions can be tweaked to produce wider kerfs and, hence, make automated parts picking out of the nest more reliable. Some pickers stack similar or identical pieces individually, while others lift entire nests in one operation. The nesting and automated sorting take the needs of downstream operations into account—like grain direction requirements in forming. All of this might require strategic microtabbing of certain parts in the right places, perhaps even strategic placement of the slats themselves. And in this situation, a change in customer priority wouldn’t create a bottleneck; material handlers Monday morning would simply retrieve parts stacked on a different pallet, no digging required.

“All these puzzle pieces keep parts on the move downstream to forming, an area that has undergone dramatic changes in recent years thanks in no small part to the industry’s increased blanking capabilities. Bending advancements include offline bend programming, various angle correction systems, and, not least, automatic tool change and robotized bending.

“Knowledge lies at the heart of disruptive technology—knowing exactly where jobs are, knowing the touch time (when and for how long cutting, bending, welding actually occurs), and its relationship to overall lead time. Modern computers can track many of these variables, but can they predict them? Many times, yes, but not always.

“That’s according to Mark Lilly, president/CEO of software provider LillyWorks, who put problems into two categories: those that algorithms can solve in a reasonable amount of time, and those that are so complicated that it would take algorithms years or even many lifetimes to process.

“’Some problems are so complicated, the solve time is so out there, you can just forget about it. You won’t find a solution within your great-great-grandchildren’s lifetime.’

“Precise job scheduling falls into this category, which is why in reality jobs spend most of their time on the shop floor waiting for the next operation. It’s impossible to predict the exact amount of variability a shop will experience, be it a last-minute order change, an unexpected employee absence, or anything else.

“The goal is to achieve flow amid all this unpredictability. For this reason, Lilly recommended shops schedule based on several factors. First, anticipate the variability to establish the time buffer needed, based on the overall lead time’s relationship to the actual touch time for the job. These buffers determine how much work should be released as WIP. The more WIP you have, the longer the lead time.

“With this determined, shops can prioritize orders not by their due date, but by those that are most in danger of being late. A cutting-only job might be due the next day, but because its routing is simple, it’s not in great danger of being late. A job due a week later might have a complicated routing that involves outside processing. Despite the far-out due date, the job might be in greater danger of being late and, hence, should be given priority.

“Although it’s impossible to eliminate every variable in the shop, such approaches to production management give everyone better context. That in turn brings everything one step closer to autonomous manufacturing, where software and machines make decisions on their own to adapt to changing demand. Operators don’t ‘operate’ machines in the traditional sense but instead become process managers, turning their attention to customer priorities and away from the minutia of every cut, bend, and weld made on the floor.

About Feeling Compelled

“All this change is happening right when hiring has become more difficult than ever, and it’s not just about skill. Finding people who care—not just about themselves and their job performance, but about the organization—has never been more critical.

“This was perhaps the most significant takeaway from Darren Woodson’s keynote. The former safety for the Dallas Cowboys and commentator for ESPN is now a commercial real estate entrepreneur and business owner. At the conference Woodson spoke of four types of people, or the ‘four C’s,’ as he called them. First are those who are content with the status quo. ‘The content will cost you,’ he said. Next comes the compliant. ‘They’re the cousin of content. They comply with the rules, but you need to hold their hand.’

“Then comes the committed, those who arrive early, stay late, and seem like top performers—yet they’re just concerned about their own performance. It’s about them, not the team. An industry analogy might be a star press brake operator who gets the job done and yet doesn’t coach or work well at all with others. That star brake operator might be able to create a complicated stage-bend setup like no one else, but that feat can be automated to some degree. Coaching and being a team player, not so much.

“The fourth of Woodson’s C’s should thrive in the modern business environment: the compelled. ‘As business owners, you need to look for the compelled,’ he said. ‘They constantly tell themselves, ‘I need to do better,’ and their entire mission is to serve.’

Asking Big Questions

“Compelled people at a fabricator (or elsewhere in the metal fabrication supply chain) question the status quo and act on the knowledge that disruptive technology gives them. In fact, technology is prompting some business leaders to question not just individual fabrication practices, but also the business model of metal fabrication itself.

“’IIoT will change the relationship you have with your suppliers,’ The MPI Group’s Brandt said, illustrating the point with a surprising fact: Many airlines don’t ‘own’ the jet engines that power their planes. They don’t pay for the engines themselves, only their use and maintenance. Embedded sensors detect when the engines are in use, how they’re used, and help predict when those engines need maintenance. Perhaps most significant, this turns that engine into a cost reported on the income statement; it’s no longer a capital expense.

“He went on to describe a similar arrangement that a packaging machine-maker has with its customers: that is, customers pay for the time the machine produces, but they actually don’t “own” the machine itself. Riffing off software as a service (SaaS), you could call it ‘manufacturing machinery as a service.’

“Paying for machine time would incentivize fabricators to make the best use of available capacity and eliminate the need to even think about machine utilization to recoup a machine investment. A fabricator would pay a machine vendor not for the equipment, but for its use. Those fabricators that run their equipment less and yet sell more (think strategic nesting, setup reduction, scheduling, and cross training) would edge out competitors.

“The devil’s in the details, of course, and how practical this would be remains to be seen. Regardless, with all the disruptive technologies out there, industry leaders are at least starting to ask big questions, which, when you get right down to it, is what the FMA Annual Meeting is all about. They’re asking not just about how to cut, bend, or weld a part faster and better, but about how they can improve entire supply chains and the business models within them.”