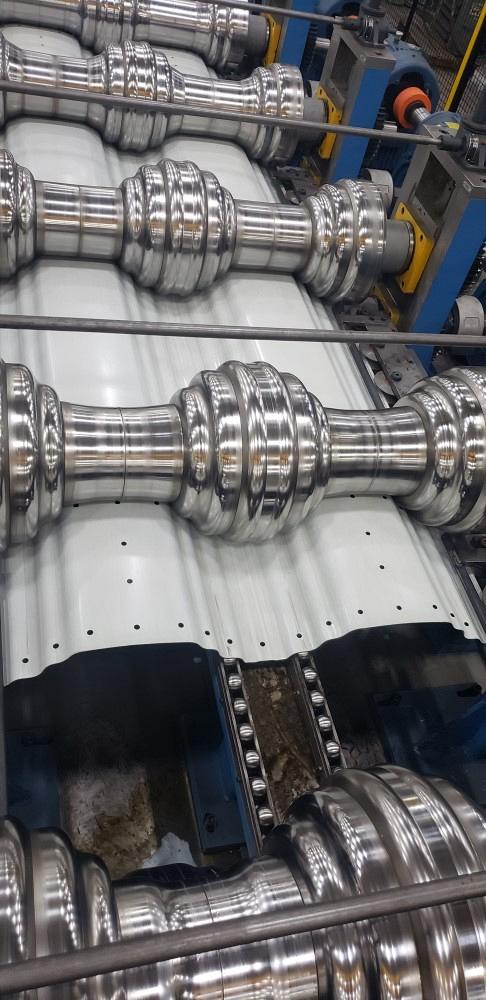

Roll forming is a process in which a strip or sheet of metal, such as steel, is passed through a continual set of stands (rolls) until the desired cross-section profile is achieved. The sheet or strip is plastically deformed along a linear axis in a room temperature environment. Typically used to create parts featuring long lengths, roll forming is also useful for manufacturing large quantities of a specific shape.

Each stand in the roll forming process has a specific job in the fabrication of the piece, and every stage involves minor changes in the configuration of the metal. The size of the stands used depends on the metal’s type, thickness, and formability.

Ferrous Metals

Ferrous metals are any metals that feature a bivalent iron compound. Some examples of ferrous metals include:

Steel: made up primarily of iron and malleable below its melting point by at least one temperature range without requiring special heat treatment. Steel for roll forming is usually free from slag and between 0.05 and two percent of its weight is carbon. Steel can also contain small amounts of silicon and manganese, as well as trace quantities of sulfur and phosphorus.

Stainless Steel: contains a high percentage of chromium, which lends it high staining and corrosion resistance. This form of steel is also resistant to weak mineral acids, oxidation, organic acids, and other caustic materials.

Galvannealed: sheet steel that has been coated on both sides with zinc and immediately heat treated so the surface of the metal features a bonded coating of zinc-iron alloy.

Non-Ferrous Metals

Non-ferrous metals do not feature any iron in their chemical makeup. Some of the more common non-ferrous metals used in roll forming include:

Aluminum: a soft, malleable, and lightweight metal with excellent resistance to corrosion. When exposed to air, it forms a thin layer of aluminum oxide to protect it from wear.

Brass: a copper and zinc alloy featuring a bright, gold-like color and a high resistance to corrosion. There are a number of different types of brass, including bronze, an alloy of copper and tin. Brass is very malleable and is used in a variety of applications.

Copper: a ductile metal noted for its electrical conductivity. It also features prominently in building materials and as a primary component in other non-ferrous alloys.

Lead: used in many types of building supplies such as roofing metal, flashing, gutters, gutter joints, and others.

Composites: materials engineered from two or more materials with chemical or physical differences.

Read more: Materials Used In Roll Forming