Laser Beam Welding (LBW) is a welding process, in which heat is generated by a high energy laser beam targeted on the workpiece. The laser beam heats and melts the edges of the workpiece, forming a joint.

The energy of a narrow laser beam is highly concentrated at 108-1010 W/cm2, so a weak weld pool is formed very rapidly (for about 10-6 sec).

The solidification of the weld pool surrounded by cold metal occurs as rapidly as the melt. Since the time the molten metal is in contact with the atmosphere is low, there is no contamination and therefore no gradient (neutral gas, flow) is required.

In laser welding (LBM) the joint is made either as a sequence of overlapped spot welds or as a continuous weld. Laser welding is used in the electronics, communications and aerospace industries, for the manufacture of medical and scientific equipment, joining small components.

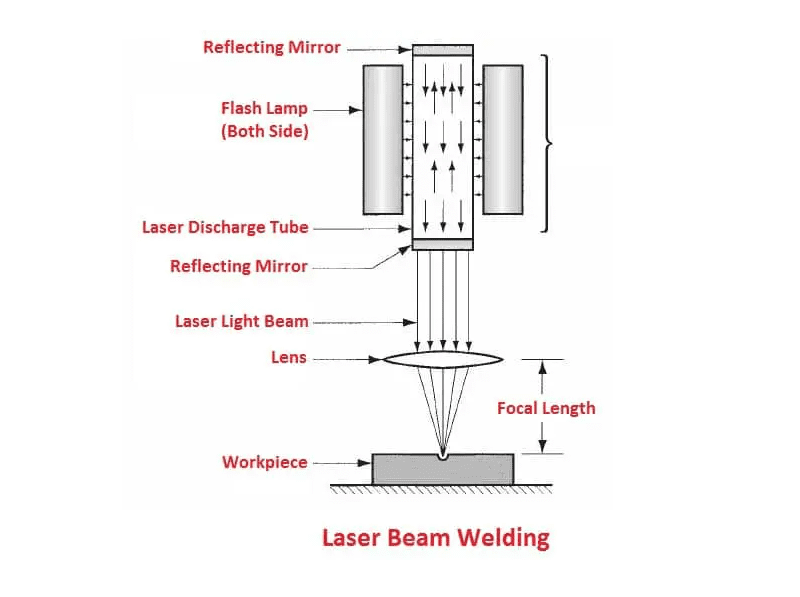

The laser beam welding works on the principle that when the electrons of an atom are excited by receiving some energy. And then after some time when it returns to its ground state, it emits a photon of light.

The concentration of this emitted photon is increased by the excited emission of radiation and we get high energy focused laser beam. The light amplification by stimulated emission of radiation is named as a laser.

Read more: LASER BEAM WELDING: WORKING, TYPES OF LASER USED, APPLICATIONS