The fundamental concepts behind roll forming go back to Leonardo da Vinci. The first continuous roll forming lines can be traced back to the 1910s. Yet even after all this time, many still don’t know what roll forming really is. It’s a staple in certain sectors like automotive, aerospace, and the metal building industries, but to many the century-old metal forming technology remains entirely novel.

Knowing just what roll forming can and cannot do opens the door to a host of metal forming possibilities. And in most cases, it all starts with a continuous part profile with high-volume requirements.

Roll Forming 101

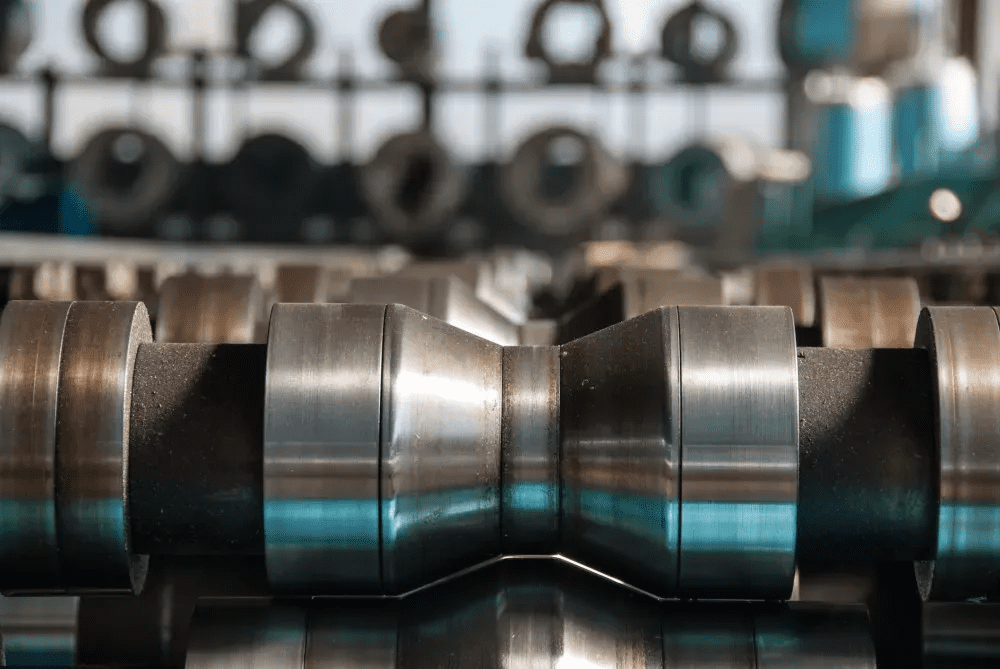

Even those who do know roll forming continue to be amazed about what’s possible. These days some manufacturers have developed proprietary methods to push roll forming’s limits, coining the metal to produce a part profile that looks extruded, not formed from a coil of sheet metal. Others have found ways to form shapes with noncontinuous cross sections, like a C-channel that “squeezes in” like a bowtie.

But most conventional roll forming applications still require a continuous cross section, or profile. It could be a simple C- or U-channel or an incredibly complex, irregular shape. The part can be straight, curved, even twisted into a helix. But amid all this geometric variety, the part profile is continuous.

To understand why requires a basic understanding of the roll forming method (see Figures 1 and 2). Material emerges from a coil or blank through a precision leveler (if the application requires it), and then into the first stand of a roll forming line. The upper and lower roll tools on every stand perform a certain amount of forming that together create what’s known as the roll form flower, an illustration showing how a part is rolled to its finished profile.

As the metal strip feeds through, the upper and lower roll tools on each stand form the profile a specified amount that depends on the metal thickness, grade, material yield and tensile strength, part geometry, feed rate, and other variables. And just like stamping and press brake forming, roll forming must deal with springback. The metal forms as it squeezes through the first set of rolls, then relaxes slightly (thanks to springback) before entering the next roll set or forming pass. That next station forms the piece to the next “petal” of the flower pattern, accounting for previous springback from the prior pass. And so the process continues until it reaches a straightening station, or sweep block, which eliminates or induces camber (see Figure 3), before being completed or cut to length at the end of the line. The resulting parts can be straight, curved, or even formed into a helix pattern.

Read more: Is roll forming an option?