Sheet metal embossing is a stamping technique that creates raised or sunken images in sheet metal. This procedure can be accomplished using matched male and female roller dies, or by sliding a sheet or a strip of metal between the desired pattern’s rolls. It’s frequently used in conjunction with foil stamping to create a gleaming, three-dimensional impression. Depending on the sort of embossing required, metal sheet embossing is generally achieved using a combination of heat and pressure on the sheet metal. The metal thickness is modified in its composition, in theory, using any of these processes.

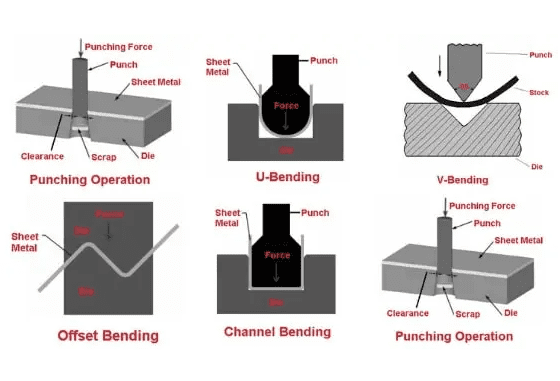

In this article, you’ll learn the various types of sheet metal operations with their diagrams.

Types of sheet metal operations

The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations.

Shearing Operations

The Shearing operation is a cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal that is sheared or cut. In this operation, a sheet metal workpiece is placed or kept between two dies from one end. And, the punch is hit at the other end of the sheet, producing a shearing effect. This type of sheet metal operation has three basic stages:

Plastic deformation occurs when a metal is sandwiched between the upper and lower blades of shear when pressure is applied. It penetrates the metal for around 5 to 40% of its thickness.

A fracture occurs at the spot where the most stress is concentrated.

Shear – The metal is sheared once small fractures are discovered.

Read more: Different Types of Sheet Metal Operations with diagram