How is CNC machining used in the Aerospace sector? Consider this.

According to LinkedIn:

Aerospace Engineering is a type of engineering with little room for error – the very nature of aerospace engineering requires utmost accuracy, accountability and efficiency. Many aerospace parts are tested, configured and produced using CNC Machining.

Ways CNC Machine Can be Used in the Aerospace Industry Sector

Utmost precision is ideally met with every engineering project and component or part created. This is a particularly pressing concern when it comes to aerospace components – when dealing with flight, accuracy is everything – every single component of a plane will require precision and accuracy to ensure safety and assurance in flight.

What are the main features of CNC Milling for aerospace?

1) High precision manufacturing

2) Variety of parts and complexity

3) Lightweight materials of high strength

Considerations need to be made when it comes to aerospace parts and structures, be that for everyday air travel, space aviation or the defence industry. When considering spacecraft in particular, longevity, as well as precision, will need to be considered.

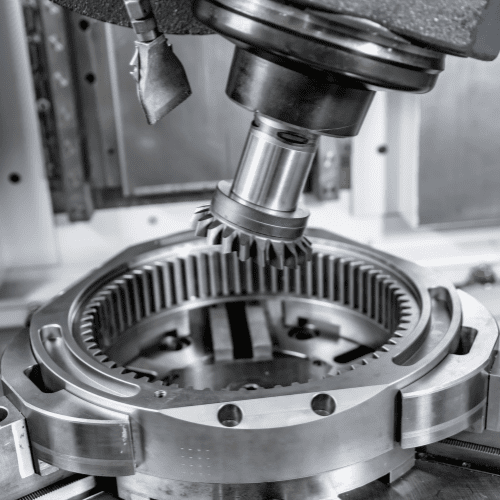

This means that every single component needs utmost precision and no room for error. This is where CNC Machining comes into play. CNC machining for aerospace parts has paved the way for more accurate and cost-efficient results than ever before. With such an array of parts, components, structures, that all require varying levels of machining, moulding, and additive manufacturing, automated manufacturing has become increasingly popular. The Boeing 747, for example, is made up of 6 million separate parts.

Aerospace Milling with 5 Axis CNC

Considering the complexity and variation of aerospace parts, it makes sense that many aerospace parts are configured using 5 Axis CNC machines.

The machine set up allows for complex geometries, and, as space travel and aerospace is an ever-evolving industry, the machine set up allows for continuous adaptation and reconfiguration of parts.

In a nutshell, 5 axis CNC machining copes better with the scope and technicality of aerospace components so they can be milled, drilled or manufactured to the specifications of the individual aircraft. Additionally, 5 Axis CNC Machining can easily suit the rigorous, high performance demands of the aerospace industry.