Machinists and toolmakers are a hardy bunch and fear little. Many have conquered the world of manufacturing with little more than a set of micrometers and a file. Most have survived encounters with engineers, quality inspectors and dreaded safety professionals.

The only thing that scares this group of crusty manufacturing professionals is difficult-to-machine materials. Being assigned to machine tap-breaking, drill-dulling and generally aggravating metals like stainless steel, Hastelloy and Inconel is the main anxiety for these pros. They all look forward to aluminum jobs.

Aluminum is light, clean and easily machined, which is why machinists enjoy working with it. Aluminum alloys arrive without scale, dirt and oils because aluminum manufacturing processes are cleaner than those for other materials. Aluminum is also one of the least dense materials commonly used for manufacturing, making the metal easy to handle. Most importantly, it is a ductile material, which makes fabrication and machining processes uncomplicated.

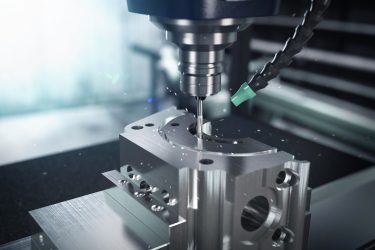

People sometimes ask, “How fast can you machine aluminum?” The answer is as fast as a machine will run. Because aluminum is easy to machine, there is a broad range of effective cutting speeds. Aluminum is very forgiving and can be machined successfully using a wide extent of cutting parameters. The merciful nature of aluminum makes it an ideal material for training students, proving out new CNC programs and creating cool machine tool demonstrations at trade shows.

Challenges

Although machining aluminum can be easy, the characteristics that make it simple to machine may pose challenges, especially when presented with high production quantities, stringent cycle requirements and close tolerances.

Read more: All about aluminum