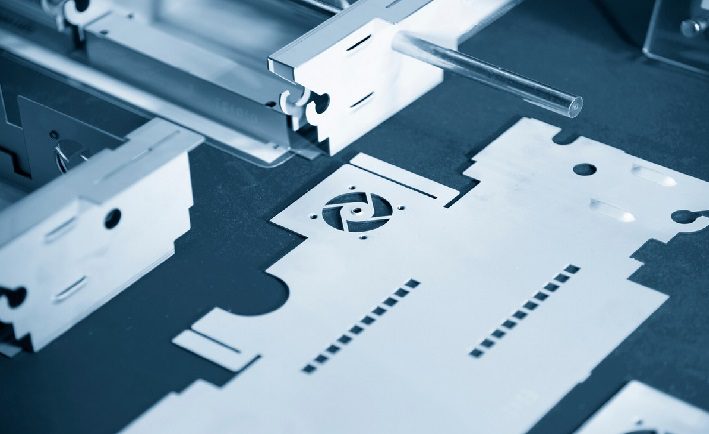

Punching is a common method of metalworking that can be used to transform metal materials into desired shapes, sizes or other properties. Through the punching machine, various complex metal parts can be produced, which greatly improves the production efficiency of the product.

Over the past ten years, as the punch presses have become more functional, the software has become more powerful, and the personnel have developed a very good level of specialization. Therefore, how to use the most advanced CNC punching machine to achieve the best equipment has become one of the key factors to measure the competitiveness of enterprises.

What is A Punch?

Punch press (stamping press), also known as stamping machine, which is divided into manual and pneumatic. It uses preforming dies and pressure to create sheet metal blanks into shaped products and components. Manufacturers use automatic or manual feeders to insert the sheet metal into the punch between the die and the die surface. The press lowers the sheet metal using the compressive force to force the material into the mold to form the desired shape.

Metal stamping is a versatile punching process that produces accurate, uniform products quickly and efficiently. The process is used in both large and small production runs and is often combined with other metalworking processes such as machining, assembly and finishing.

There are many specialized punching techniques that can be used to produce specific effects, including:

- Punching: involves the use of dies and presses to punch holes in workpieces.

- Blanking: punching the workpiece out of the metal slab.

- Embossing: use raised or indented text, graphics, and designs in sheet metal.

- Casting: similar to embossing, but with raised or indented text, patterns, and graphics embossed on both sides of the workpiece.

- Bending: using a bending machine, force is applied to a metal workpiece, which bends the metal workpiece into a V or U shape from its original axis.

- Flange: the edge of the workpiece around the punched hole is bent at a 90° angle to the sheet, forming a lip around each hole.

Working Principle of Punch Press

The working principle of the punch press mainly converts rotary motion into linear motion. The main motor provides the power to drive the flywheel. Through the clutch and connecting rod, the flywheel drives the crankshaft or eccentric gear to convert the surrounding motion into linear motion. There is a need between the slider and the connecting rod. During operation, the driving structure provides power for the up and down movement of the ram, opening and closing the upper and lower molds.

In recent years, in addition to punch processing, various processing modes have emerged, such as 5 axis CNC machining service, vacuum casting, 3D printing, sheet metal processing, etc., especially 5-axis processing is more widely used in various industries. Its processing has the advantages of reducing production time and processing time, and has a single setting function, which can process parts with complex structures and special shapes, and is specially used for processing complex surfaces.

In this process, a metal strip is passed between the die blocks, and as the punch moves down, pressure is applied to the metal plate and a hole is cut, and the separated part falls through the die opening.

Read more: What is A Punch? Punch Principle, Type, Material Introduction