Did you know the mining industry uses CNC machining?

According to LinkedIn:

The mining industry in Australia is a major contributor to the GDP. In fact, mining contributed an all-time high of A$26.7 Billion to the GDP (or 9% of the total) in the second quarter of 2018.

Such large mining operations, rely heavily on a healthy manufacturing industry for support. There can be no stopping of operations and mines churn through manufactured components due to the harsh environment. So a strong supply chain of CNC machining companies is vital.

The importance of maintaining production at all costs means that these parts need to be of the highest quality, and also be readily available. Such a reliance has created a flexible, adaptable, competitive domestic CNC machining sector. A sector all domestic manufacturers should draw upon for machined parts.

This article will take a look at the various types, and advantages, of CNC machined parts within the mining industry.

Advantages of CNC Machined Parts for the Mining Industry

CNC machined parts offer a range of advantages for heavy duty mining equipment, such as:

Rapid production – Mines cannot afford downtime; mere hours can result in millions of dollars in losses. Therefore, there is no time for manually machined or cast parts.

Quality – Despite the emphasis on production, safety is always the No.1 priority. As such, all parts need to meet a stringent set of quality requirements. No other technology can generate quality repeatedly and reliably like CNC machining.

Production volume – A dialled in CNC machine can produce hundreds or even thousands of parts per production run. No other heavy engineering technology can meet this production cadence.

Tooling flexibility – One off emergency or custom parts do not require re-tooling, as is often the case with injection molding or other mass production technologies.

Design flexibility – Parts can be designed in a CAD package and can be made ready for machining in very little time and all by the same person. This all-digital workflow dramatically increases efficiency.

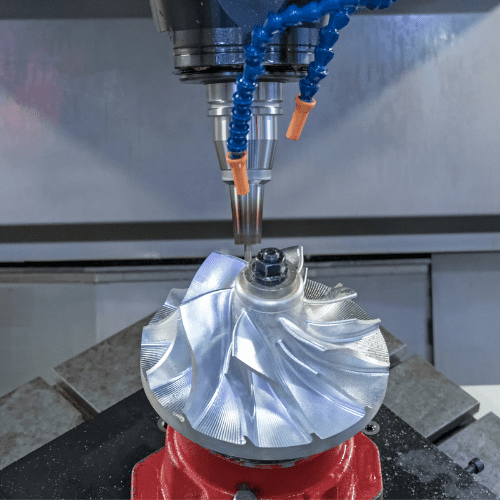

Typical Parts for the Mining Industry

The mining industry is incredibly complex and has a long list of processes to reach the final product. The shear number of machines that are used on a typical mine is staggering, a list of every part that can benefit from CNC machining would be far too long for a single article, however the list below gives a general idea of the types of parts that can be manufactured using CNC machines.

1. Gear Blanks

Although it is possible to manufacture gears on a CNC mill, it is not the most efficient process; gear cutting is better suited to specialised gear cutting machines. However, gear blanks can be manufactured on CNC machines. These blanks are made to be the same overall diameter and width as the required gear. These blanks are then transferred to the gear cutter.

2. Shafts

In some cases, a shaft can fail due to either fatigue failure or sudden overloading. A failed shaft can bring any machine to a grinding halt. A CNC lathe can easily manufacture a shaft to a high degree of accuracy. More advanced machines can even machine keyways and other features without having to transfer the part to a CNC mill.

3. Gearbox Housing

Gearboxes can be found in every mining process, from the gearboxes on large hauler trucks all the way to gearboxes on large SAG mills. As such they are often subjected to extreme operating conditions and can be damaged to the point of failure. A gearbox housing is formed from a complex shape and is typically cast, however having a replacement part cast is time consuming and costly. CNC machines can mill out these housings much quicker with better surface finishes and tighter tolerances.

4. Bearing Seals

Bearing seals are designed to keep abrasive media from entering the bearing and wearing it down and ultimately seizing it. In a mining environment there is no shortage of abrasive media and as such these seals must be maintained and replaced as soon as they reach the end of their life cycle. There are various types of bearing seals. For example, labyrinth seals are mechanical seals with very tight tolerances that make contaminant ingress difficult. Due to these tight tolerances, CNC machining is the only way to maintain these tight fits.

Maintenance

Once a mine is operational, it is a mammoth task to keep the plant running. Typically there are various maintenance programs employed such as predictive maintenance or preventative maintenance. These operations require an inventory of critical spares for all major mining equipment such as draglines and excavators, or non-standard bolts and pins. A wide range of these parts can be produced using CNC machining technology.

Research & Design

There is continuous R&D in the mining industry, and new materials, components and manufacturing methods are constantly being explored. There is a never-ending drive to improve production, increase efficiency and eliminate down time. R&D is an area where CNC machines provide immense value due to their flexibility and speed.

In Conclusion

The mining industry is a notoriously tough environment for anything mechanical. As such, failures happen often, and mine managers demand that these failures are rectified as quickly as possible. CNC machine shops can provide parts of the kind of quality and speed necessary. Building a relationship with an experienced and professional CNC machinist can result in huge gains in production and efficiency.