Machining Process: It is a process in which a piece of raw material is cut into a desired shape and size by means of sharp cutting tools called a Machining Process.

1.1 Types of Machining Operations:

There are two types of machining process.

1.Conventional Machining Process

- Drilling

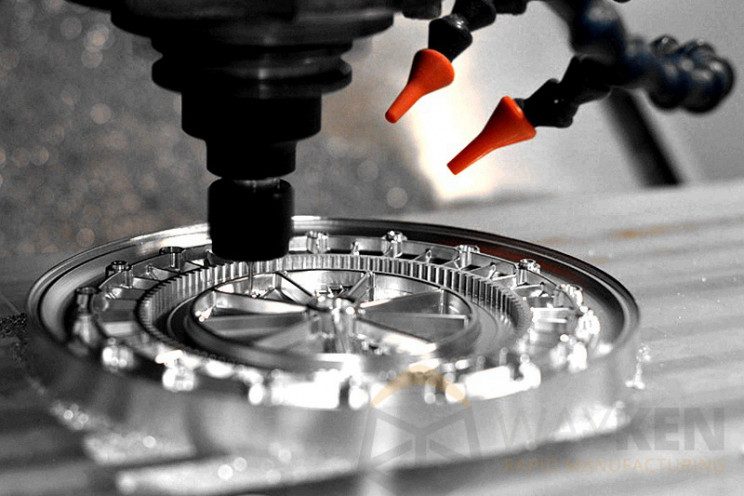

- Milling

- Turning

- Boring etc.

2.UnConventional Machining Process: An advanced to Conventional Machining processes

- USM (Ultrasonic Machining)

- EDM (Electric Discharge Machining)

- ECM (Electro Chemical Machining)

- Laser Machining

- Wire-cut EDM etc.

1.2 Advantages of Machining Process:

- A high surface finish can be obtained.

- Machining is not only performed on the metal but it also performs on wood, plastic, composites, and ceramics.

- Variety of geometry features are possible, such a Screw threads, Very straight edges, Accurate round holes etc.

- Good dimensional accuracy.

1.3 Limitations of Machining Process:

- The accuracy of the components produce is dependent on the efficiency of the operator.

- The consistency in manufacturing is not present. Hence 100% inspection of the component is required.

- The personal needs of the operator are reducing the production rates.

- Because of a large amount of Manpower involved, the labor problem will also be high.

- The complex shapes like parabolic Curvature components, Cubicle Curvature components are difficult to manufacture.

- Frequent design changes in the component cannot be incorporated into the existing layout.

To overcome the above disadvantages, the advanced machining methods like NC, CNC, DNC, FMS, etc. have been developed.

1.4 What is Machine Tool?

A machine tool is a power-driven device used for sizing, shaping, and processing of a product to the desired accuracy by removing the excess material in the form of chips.

Ex: Lathe Machine, Drilling Machine, Shaping Machine, Planar Machine etc.

1.5 What is Cutting Tool?

A cutting tool is used to remove the material from the surface of the workpiece. It must be harder than the workpiece to carry out the operation.

There are two types of cutting tools.

(a) Single-Point Cutting Tool and

(b) Multi-Point Cutting Tool.

(a) Single-Point Cutting Tool:

- A single-point cutting tool has only one edge for cutting.

- This single-point cutting tool is used as a cutting tool in turning operation.

- Other Examples include the tools used in lathe, Planing, Shaping etc.

(b) Multi-Point Cutting Tool:

- A Multi-point cutting tool has more than one edges for cutting Operation.

- This multi-point cutting tool is used as a cutting tool in the drilling operation, milling operation etc.

- Ex: Milling cutter, Grinding wheel, Drill bit etc.

1.6 What are Chips in Machining?

The unwanted material removed from the surface of the workpiece due to the application of load upon the cutting tool called as Chips.

There are two types of chips.

1.Discontinuous chips

2.Continuous chips

Discontinuous chips:

The Discontinuous chips are simply thrown away from the work zone during machining.

Continuous chips:

The Continuous chips may get adhered or welded onto the rake face of the tool due to the high temperature called as Built Up Edge formation(BUE).