Expertise

- Engineering

- Fabrication

- Welding

- Assembly

- Powder & Wet Paint

- Supply Chains

Knowledge

- Highly Skilled

- 21 Year Industry Average

- Continuous Training

- Certified Engineers/Designers

- Certified Welders

- Logisticians

Capabilities

- Small & Large Products

- Single to High-Volume Production

- Multiple Industries

- 125,000 sq-ft Facility

- Manufacturing & Warehousing

- Superior Industry Lead-Times

New Equipment, New Capabilities

- Bodor M350 Fiber Laser Metal Tube Cutting Machine

- GMC Hydraulic Plate Roller

- Roundo 3-Roll Angle Iron & Tube Roller

Full-Service Metal Fabrication & Finishing

Laser Cutting

- *NEW* Bodor 6,000 watt fiber tube laser cutting with automatic load and unload up to 39 feet long

- 49 shelf material handling system connected to a 10,000 watt Mitsubishi fiber laser with automatic load and unload

- Can run 24/7 unmanned

- Up to 1" thick 60"x120" sheets

- Amada Gemini 4,000 watt 80"x160" sheet size laser

- Amada EML 2515 AJ Turret Punch Combo Fiber Laser

Punching

- Metal & Plastics

- Thickness up to ¼”

- Sheets up to 60” wide

- Amada EML 2515 AJ Turret Punch Combo Laser:

- 33 tons Punching force

- Maximum material thickness: .25”

- Multimedia CNC control

- 3KW–wattage

- Fiber Laser

Rolling & Forming

- *NEW* Roundo CNC Tube and Angle Rolling Machine

- *NEW* GMC Hydraulic Plate Roller 4! 12 gauge 480 volt

- Four CNC press brakes

- Up to 247 Metric Ton Capabilities

- Up to 12 Foot Bending Length

- Multiple machines for sheet rolling

Welding

- Steel, Stainless, and Aluminum

- Mig & tig welding

- Spot welding

- Stud welding

- Plasma cutting

- Robot welding

Machining

- CNC Machining and Turning per your specifications

- Latest equipment in CNC machines and programming

Finishing

- 600-foot automated Powder Coat Line

- 2 Batch Powder Coat Booth Systems

- 150-foot Wet Paint Conveyor Line

- Large wet paint booth

- Iron phosphating and glass bead blasting

Saw Cutting

- 2 CNC High Precision Marvel Cutting Saws with Automatic Feed

- Up to 60 degree automated angle cutting in half-degree increments

Stamping

- Cincinnati CNC 175 Ton 10" Stroke Hydraulic Die Clamps with quick change tooling capability

Shearing

- 10 foot quarter plate mechanical shear with back gauge and CNC front gauge for accurate cutting

Suffering because of

supplier issues?

- Late Deliveries

- Hidden Costs

- Lack of Service

- Sub-Standard Quality

- Long Lead-times

- Limited Capabilities

Why Tri-State FABRICATORS?

As a family-owned company under third-generation leadership, we live and breathe metal fabrication. Our workforce has an average of 22 years working at Tri-State Fabricators.

We have a wide variety of machines and equipment, including paint and powder coating, to handle every aspect of the metal fabrication and finishing process.

We run on EOS to work smarter and at the highest efficiency. ISO 9001-2015 Certification creates a strict structure by which we operate.

Located in the heart of the Midwest, we are within a 1-2 day drive of many major cities in the United States. Our location is convenient and easily accessible.

From part prep to final product, our extensive painting and powder coating capabilities ensure a flawless finish with superior consistency.

Situated on 20-acres with a 125,000 sq-ft facility, we have the latest machines and technologies to cover every aspect of metal fabrication and finishing under one roof.

NEW MACHINES, EXPANDED CAPABILITIES

Tri-State Fabricators continually invests in the latest and most state-of-the-art technologies and machines for cutting and rolling. These are our latest equipment additions, greatly expanding our metal fabrication capabilities.

Bodor M350 Fiber Laser Metal Tube Cutting Machine

- Round, square, and rectangular tubes, angle steel, channel steel, H-beam, etc.

- Machinable tube length up to 30 feet

- Maximum tube weight: 1,100 pounds

- Synchronous dual process with four chucks and diverse clamping modes

GMC 4' x 1/4" Plate Roller 12 gauge 480 volt

- Bends and rolls sheets or plates into cones and other cylindrical shape

- Hydraulic driven

- Roll capacities: Mild steel - 4' x 1/4"

Stainless Steel - 4' x 3/16"

Soft Aluminum - 4' x 3/8"

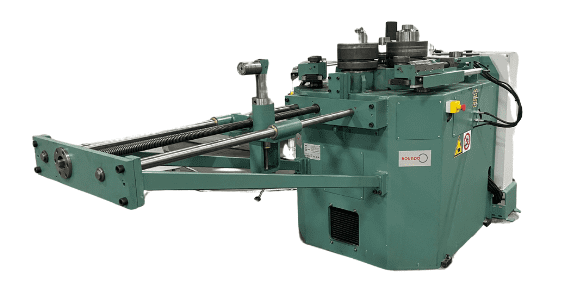

Roundo 3-Roll Angle Iron & Tube Roller

- Bending strength: 5.5 cubic inches to 7,900 cubic inches

- Six directional fully hydraulic and powerful guide rolls

- Round and square tube and pipe die sets

How does your shop stack up?

Not all metal fabricators are the same. It takes time to get the knowledge, tools, and team to truly stand out from the crowd. Download the Top-10 Metal Fab Must-Have’s List to see if your current metal fab supplier has what it takes to be one of the best.