What is it laser cutting?

Laser cutting is a technology that allows metals and some non metallic materials to be cut with extreme precision if required. The laser beam diameter is typically between 0.1mm & 0.3 mm with a power of 1-3 kW, the power is adjusted depending on the type of material being cut and the material thickness. Laser powers of up to 6kW are needed to cut through a reflective material such as aluminium. .

Types of laser cutting

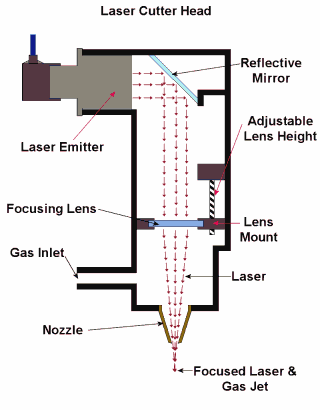

Depending on the application of the laser cutter a selection of different gases are used in conjunction with the cutting. For general boring, cutting and engraving then Co2 is typically used.

If high powered laser pulses are used then neodymium (Nd) gas is required, this set up is mainly associated with boring. For a constant high powered beam neodymium yttrium-aluminium-garnet (Nd-YAG) is used.

Gaseous laser cutting uses an electrical current pumped through the gas which gives the laser its cutting properties, however this has recently been revised and RF energy is now preferred as this method does not require the use of electrodes like the DC current does. These electrodes were susceptible to erosion

What can it do?

Laser cutting can cut through a wide range of different materials, these can range from acrylic, wood, paper and foam core to high carbon and stainless steels, Laser cutting is not best suited to metals such as aluminium and copper alloys as they have good heat conductive and light reflective properties, these materials require the use of a more powerful laser. Laser cutters are generally best suited to thin materials of <12mm but can cut through materials around 25mm.

Advantages

Contamination of materials while laser cutting is reduced as there is no real physical contact between metal and cutter.

Laser cutting has great accuracy as a laser can be focused into very small points and can be computer controlled with great accuracy, there is also no wear in a laser while it is cutting as there is with more conventional methods, such as milling.

There is a reduced chance of warping the material when laser cutting as the laser only generates a small area of heat when compared to plasma cutting.

Laser cutting can be more energy efficient than plasma cutting.

No mechanical force is applied therefore no physical damage can occur.

Disadvantages

Laser cutting has high energy consumption, and can draw a lot of power to perform its cutting. Although it uses a large amount of power it goes some way to making up for this cost with its fast and precise cutting speed. The cost and setup of a laser cutter can also be expensive when compared to other methods.

Work hardening along the edges of cuts can mean harder work if any further machining is required.